Trusted Source for Reliable Puf Roof Panel

Characteristics and Diversification in Roof Panel Manufacturing

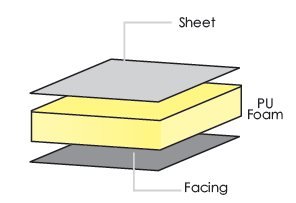

Facing

thickness

Thickness Available:

30mm 40mm 50mm 60mm 80mm100mm120mm

Insights into Roof Panel Manufacturing: Crafting Quality Roof Panels

Insulation – Heat Proof

Fast To Construct

Puf Panel Manufacturing involves manufacturing the panels at the factory, allowing for quick and straightforward installation on-site. This efficient manufacturing process reduces installation time and effort.

Engineered with advanced PUF insulation, this product is among the most efficient and high-performing options for thermal control. Its superior quality and performance contribute to significant reductions in cooling and heating costs, making it an excellent choice for energy-efficient solutions.

Strong Load Bearing

These roof panels are designed to endure compressive loads of up to 1 ton per square foot and can support significant live and dead loads when extended. The manufacturing process ensures high strength with minimal need for additional support structures, offering durability and efficiency in construction.

Edge Protect Technology

Introducing EDGE PROTECT technology, an innovative weatherproof coating for sealing sheet steel edges. This breakthrough safeguards against corrosion and rust, enhancing durability and significantly extending the lifespan of roof panels. It ensures better performance and resilience in harsh conditions.

Weather Shield For Ultra Long Life

Roof panels feature the innovative Weather Shield coating, an extra-thick, UV-resistant layer of paint that provides superior protection against sunlight and harsh weather conditions. This ensures exceptional durability and long-lasting performance.

Technical Specifications of Manufactured Roof Panels

| Panel thickness available | 30mm, 40mm, 50mm, 60mm, 80mm, 100mm, 120mm |

| Panel total width | 1070mm |

| Panel effective width | 1000mm |

| Panel length available | 1000mm-15000mm |

| Density | 40± 2kg/m3 |

| Thermal conductivity | 0.024-0.03 W/m |

| Temperature range | -40+800C |

| CFC / HFC | Free from CFC / HFC |

| Type of foam | B1, B2, B3, PIR |

| Heat transfer co-efficient | -0.022W/M2*k |

| Pressure | 0.10Mpa |

| Top coat | 5 + 15 micron |

| Back coat | 5 + 5 micron |

| 500h (ECCA TB) | 100 h (ASTM D 2247) |

CLASSIFICATION BASED ON THICKNESS OF PANEL

50mm puf panel

50mm panels are the most ideal thickness of puf sheet. They offer the best mix of insulation, strength and cost. These are a good choice for all constructions like roof top room, hospital floor, school classrooms, roof top restaurant construction, penthouse etc.

30mm puf panel

30mm panels are the most economical type of panel. They are a good choice as an alternative for metal roofing sheets.

65mm puf panel

65mm panels are a good choice for applications where high levels of insulation are required and where extreme cold or heat is a concern, such as refrigerated warehouses and cold storage facilities

40mm puf panels

40mm panels are thicker than 30mm panels and offer more insulation and strength. They are a good choice for applications where budget is is important factor, such as servant classrooms, staff quarters, temporary offices etc.

105mm puf panel

105mm panels are the thickest type of panel available. They offer the highest levels of insulation and are a good choice for applications where extreme cold or heat is a major concern, such as sub-zero refrigerator, cryogenic chambers and blast freezers.

All things you need to know

Clean roof panels offer durability, UV resistance, and energy efficiency. With advanced coatings, they ensure long-lasting protection against weather and corrosion.

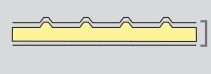

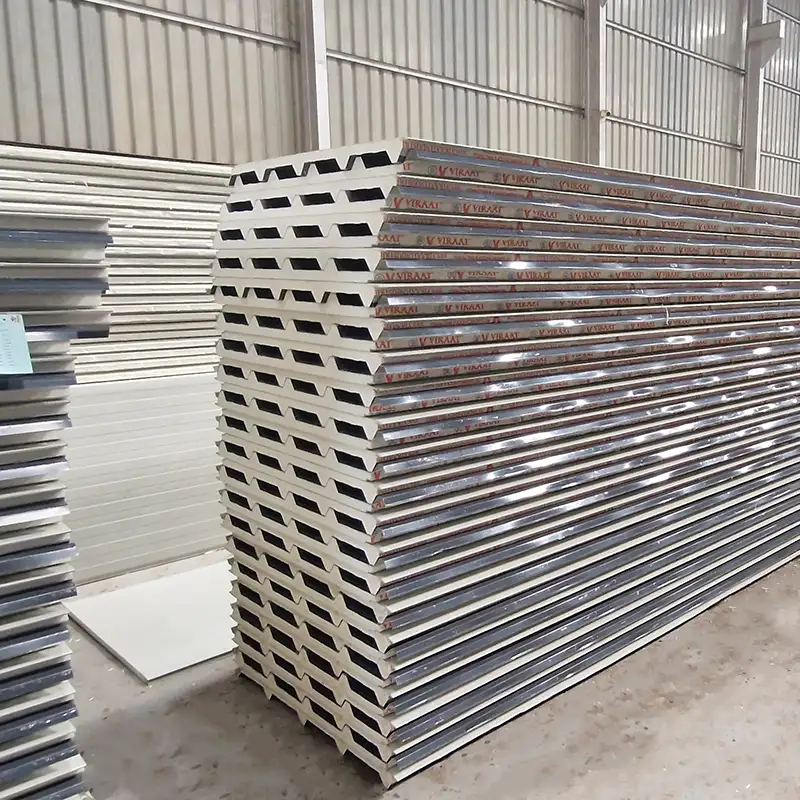

Puf Roof Panel

Roof Panel Manufacturing ensures products capable of withstanding demanding conditions. Offering a variety of finishes and colors, these panels seamlessly blend into any office or home design. Suitable for use in warehouses, PEB industries, small spaces, and farmhouses, they boast both elegance and enduring strength. The Panel is Manufactured in a Continuous Line Production Method & compromises of 5 corrugation, 250mm Pitch with exterior baby ribs for extra strength.

Polyurethane Foam Density of 40+- 2kg/m3 with Guard Film Protection on all exposed surface & confirms to IS12346.

Weather Endurance

Withstand harsh climates effortlessly.

Energy Efficiency

Maintain optimal temperatures, saving on energy bills.

Versatile Application

Ideal for diverse spaces, from warehouses to residential homes.

Get a quote for your project and unlock unbeatable solutions tailored just for you

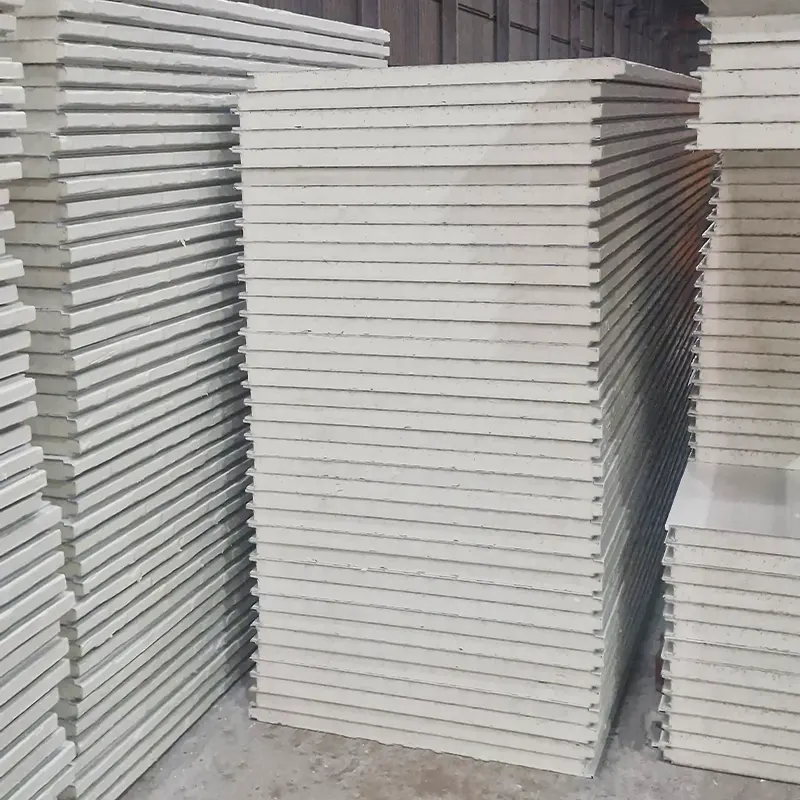

Puf Wall Panel

Wall Panel Manufacturing offers an economical solution for standard roofing needs, outperforming traditional options such as brick and aluminum in terms of cost-effectiveness. These prefabricated roofing panels are versatile, serving well in both commercial and residential contexts. Constructed with a lightweight yet durable polyurethane core encased between sturdy steel sheets or cement boards, they ensure longevity and straightforward installation.

Cost-Effective

40% to 50% cheaper than conventional walls/partitions.

Easy Installation

Lightweight design for effortless setup.

Versatile Design

Options for various thicknesses, colors, and textures.

Get a quote for your project and unlock unbeatable solutions tailored just for you.

Clientele